Understanding BGA PCB Assembly Basics

What is BGA PCB Assembly?

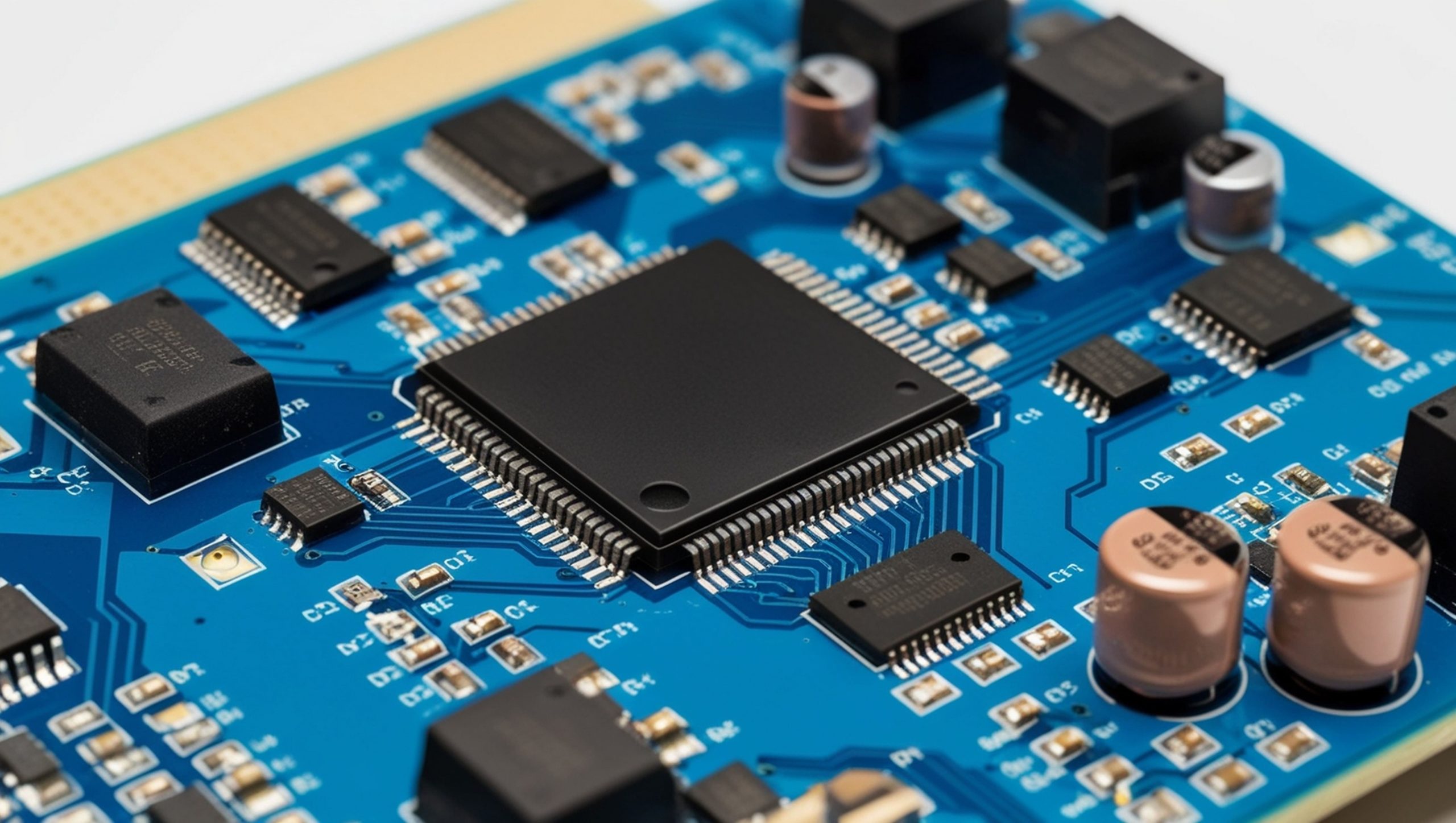

BGA PCB assembly, or Ball Grid Array (BGA) assembly, is a sophisticated technique used in the mounting of semiconductor devices onto printed circuit boards (PCBs). BGA technology features an array of solder balls on the underside of the chip, which are precisely aligned with pads on the PCB. During the assembly process, these solder balls are melted to create solid electrical and mechanical connections. This method is notably favored for its ability to accommodate high-density integrated circuits, enabling manufacturers to design compact yet powerful electronic devices.

Understanding the intricacies of bga pcb assembly is crucial for engineers looking to enhance both performance and reliability in electronic designs. The evolved nature of this assembly technique allows for better heat dissipation and minimizes signal integrity issues, making it an attractive choice for applications requiring robust performance.

Advantages and Disadvantages of BGA PCB Assembly

The BGA assembly process comes with a unique set of advantages and disadvantages that should be carefully evaluated.

Advantages

- Higher Pin Count: BGA packages can accommodate more pins in a smaller area compared to traditional chip packaging methods.

- Improved Thermal Performance: The design allows for better heat dissipation through the PCB, essential for high-performance applications.

- Enhanced Electrical Performance: BGA’s layout reduces inductance and capacitance, improving signal integrity.

- Automatic Assembly: The assembly process can be automated effectively, leading to increased production efficiency.

Disadvantages

- Assembly Complexity: BGA assembly requires precise alignment and controlled soldering conditions, which can complicate manufacturing processes.

- Inspection Challenges: The solder balls are not visible after reflow soldering, making it difficult to inspect connections visually.

- Rework Difficulties: Repairing BGA assemblies can be complex and requires specialized rework equipment.

Key Components of BGA Assembly

To grasp the BGA assembly process fully, it’s essential to understand the key components involved:

- Ball Grid Array Package: The actual component featuring solder balls that connect to the PCB.

- Printed Circuit Board (PCB): The substrate on which the BGA and other components are mounted.

- Solder Paste: A mixture of metal particles and flux used to attach the BGA to the PCB.

- Reflow Oven: An essential machine that heats the solder paste until it melts and solidifies to create the electrical connections.

- Stencil: A template used to apply solder paste accurately onto the PCB pads before component placement.

Essential Steps for BGA PCB Assembly Process

Preparation and Design Considerations

Before beginning the BGA assembly process, thorough preparation and design considerations must be taken into account. This includes:

- PCB Layout: Design consideration for pad layout, trace widths, and spacing to ensure proper solder ball alignment.

- Solder Paste Application: Using a stencil for consistent solder paste application to avoid issues with soldering and connections.

- Design Rule Checks: Performing DRCs on PCB artwork to find potential pitfalls such as pad sizes and via locations.

- Thermal Pad Geometry: Designing thermal pads to ensure efficient heat dissipation during operation.

Soldering Techniques for BGA PCB Assembly

The soldering process in BGA assembly typically involves several intricate techniques:

- Stencil Printing: Applying solder paste to the PCB pads in a uniform manner using a solder paste stencil.

- Placement: Accurate placement of the BGA on the solder paste for optimal alignment.

- Reflow Soldering: Heating the assembly in a reflow oven where the solder paste melts, flowing into the ball contacts.

- Cooling: Controlled cooling to solidify the solder joints, ensuring a reliable connection without thermal stress.

Quality Control Measures During Assembly

Quality assurance is vital in BGA assembly to ensure long-term reliability and performance:

- Inspection Techniques: Using X-ray inspection technology to verify solder joint integrity, especially in hidden areas.

- Automated Optical Inspection (AOI): Incorporating AOI systems to detect misalignments and solder issues.

- Functional Testing: Conducting tests to check the electrical performance of assembled boards.

- Process Monitoring: Continuously monitoring reflow profiles and solder paste application consistency to maintain quality.

Common Challenges in BGA PCB Assembly

Thermal Management Issues

Effective thermal management is essential in BGA PCB assembly, as heat build-up can significantly affect device performance. Issues may arise concerning:

- Heat Dissipation: Insufficient thermal via or pad design can lead to localized overheating and component failure.

- Thermal Cycling: Repeated heating and cooling during operation may affect solder joint integrity over time.

- Component Size: Larger BGA packages may necessitate additional thermal management strategies.

Alignment and Placement Accuracy

Precision in alignment during the assembly process is critical:

- Surface Tension: If the solder paste is too viscous, it may hinder accurate placement.

- Placement Machine Calibration: Regular calibration of pick-and-place machines is essential to achieve high placement accuracy.

- Layer Registration: Misalignment between different layers of the PCB can lead to connectivity issues.

Rework Strategies for BGA PCBs

Challenges during assembly may necessitate rework strategies, which include:

- Desoldering Techniques: Utilizing hot air or infrared equipment to carefully remove BGA components without damaging the PCB.

- Visual Inspections: Conducting thorough visual examinations post-rework to ensure quality.

- Restoration of Pads: Properly restoring pads on the PCB after rework to avoid future connection failures.

Best Practices for Optimizing BGA PCB Assembly

Using Advanced Soldering Technologies

Implementing advanced soldering technologies can dramatically enhance BGA assembly quality:

- Selective Soldering: Employing selective soldering techniques to minimize thermal exposure of sensitive components.

- Laser Soldering: Utilizing laser technology for precise control of soldering processes, especially for high-density assemblies.

- Lead-Free Solders: Adopting lead-free solder materials to comply with environmental regulations while maintaining quality.

Conducting Thorough Testing Protocols

Robust testing protocols are crucial for validating the performance of BGA assemblies:

- Initial Testing: Carrying out initial electrical testing after assembly to catch defects early.

- Environmental Testing: Subjecting PCBs to thermal cycling and humidity tests to assess durability and reliability.

- In-Circuit Testing (ICT): Incorporating ICT to verify connections and component functionality for mass production runs.

Continual Improvement Methods

Adopting continuous improvement methods can help enhance BGA assembly processes:

- Feedback Loops: Establishing feedback loops from production personnel to identify issues swiftly.

- Training Programs: Regular training sessions for workers to enhance skills and familiarity with advanced technologies.

- Lean Manufacturing Principles: Implementing lean methodologies to streamline operations and reduce waste.

Future Trends in BGA PCB Assembly

Emerging Technologies Impacting BGA Assembly

As technology evolves, BGA assembly is likely to benefit from innovative trends, including:

- 3D Printing: Innovations in 3D printing technologies for rapid prototyping and reducing lead time.

- Smart Manufacturing: The use of IoT to create smart factories that promote real-time monitoring and data-informed decision-making.

- Advanced Materials: Development of new conductive materials and substrates that enhance thermal and electrical performance.

Market Demand for BGA PCB Solutions

With the growing demand for compact and high-performance electronic devices, BGA PCB assembly will likely see increased market adoption:

- Consumer Electronics: The shift towards smaller and more powerful devices drives the demand for advanced PCB assemblies.

- Automotive Applications: The automotive industry’s push towards smarter vehicles boosts the need for advanced PCB technologies.

- Medical Devices: As healthcare technology advances, the demand for reliable and precise BGA assemblies will continue to grow.

Sustainability Practices in PCB Manufacturing

Future efforts in BGA PCB assembly will also be shaped by sustainability trends:

- Eco-Friendly Materials: Increased adoption of environmentally friendly materials and practices.

- Recycling Programs: Encouragement of recycling and reusing components to minimize electronic waste.

- Energy Efficiency: Manufacturing processes will focus on energy-efficient methods to reduce the carbon footprint.

Leave a Reply